The manufacturing of chemicals and pharmaceuticals requires precise temperature control and a dependable industrial chiller. That’s why regular maintenance makes all the difference in the longevity and efficiency of a refrigeration system. Follow these tips to keep your chiller in optimal condition and help prevent disruptions to your facility operations.

Keep a Daily Log

It’s hard to notice a discrepancy in the temperature controls without regularly logging the chiller’s performance. By keeping detailed daily logs, you’ll quickly catch any potential issues before they cause a breakdown. This history of the system’s operating conditions will also give you helpful data to analyze trends and identify control setpoints that could be improved. Logs should track all current operating conditions around the same time each day to minimize variables.

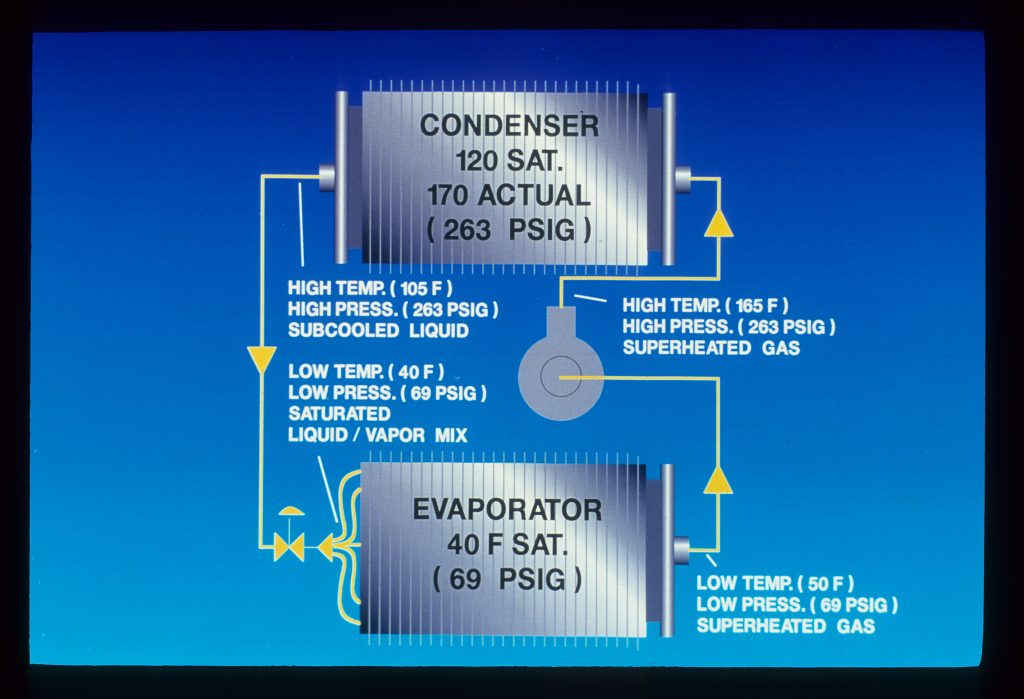

Clean Evaporator and Condenser Tubes of Water-Cooled Chillers

The tubes of water-cooled chillers can accumulate mud, algae, and other contaminants, which can hinder the system’s ability to efficiently transfer heat. We recommend that you check for build-up every one to three years, but the exact rate will depend on if you have an open or closed system and your local water conditions. Going too long without cleaning the tubes can cause erosion and long-term damage. To clean the tubes, remove the cover, gently brush the tubes, and rinse with clean water. We always recommend working with a qualified technician to conduct a thorough inspection and cleaning.

Check Chemical Levels

Yearly analysis of the chemicals in the system, including the refrigerant and oil, will help detect contaminants. Send a sample of the chiller’s lubrication oil to a qualified laboratory to conduct a spectrometric chemical analysis, which can determine if any contaminants are in the system. Possible contaminants that could hinder chiller performance include moisture, metals, and acids. A high moisture level is usually an indication of a problem with the purge unit. Oil filters should also be checked and replaced if the pressure drops to an intolerable level.

At GCI Refrigeration Technologies, we’re proud to build durable industrial chillers that will grow with your business and require minimal maintenance. We keep a detailed log of your system, so ordering replacement parts is simple and straightforward. We can also connect you to local maintenance professionals that can help keep your system operating at its best—just fill out our service form to get started. When you’re ready to replace your old and outdated chemical chiller, contact our team at 225-926-6950 to design a completely custom solution.