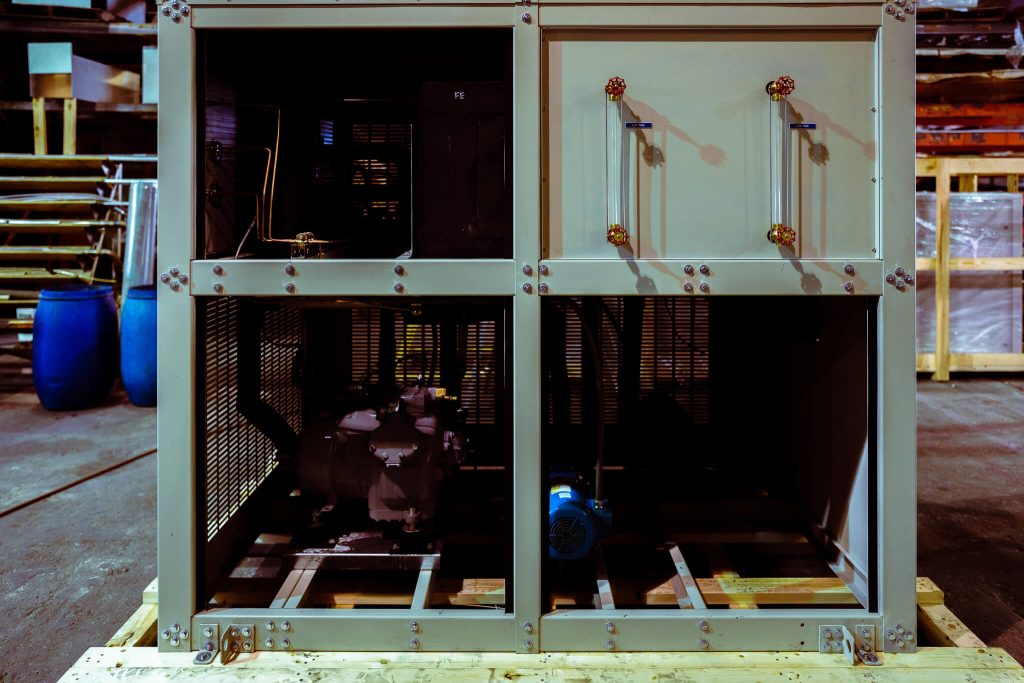

Reliable Cooling For Sub-Zero Applications

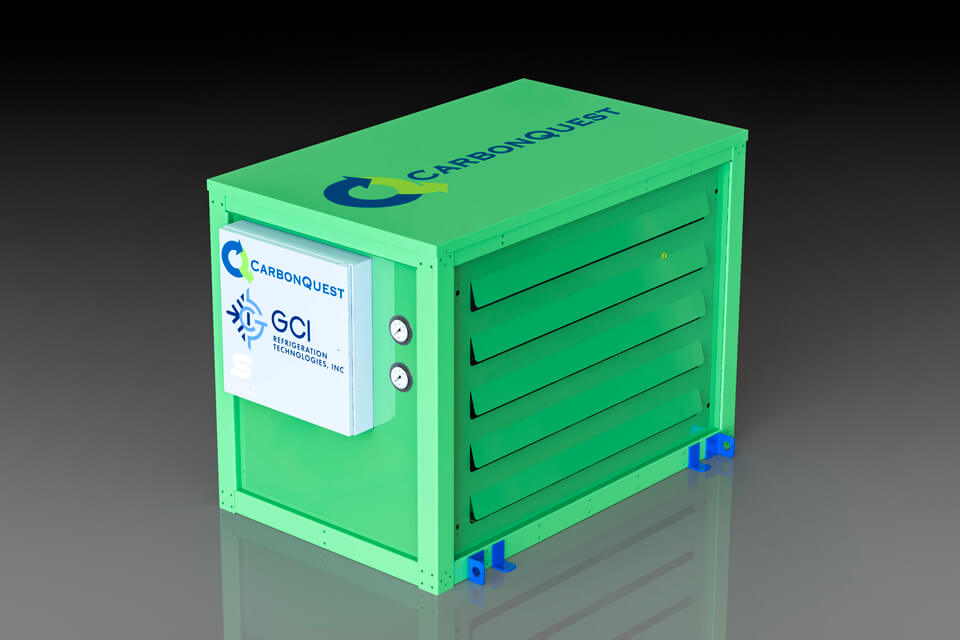

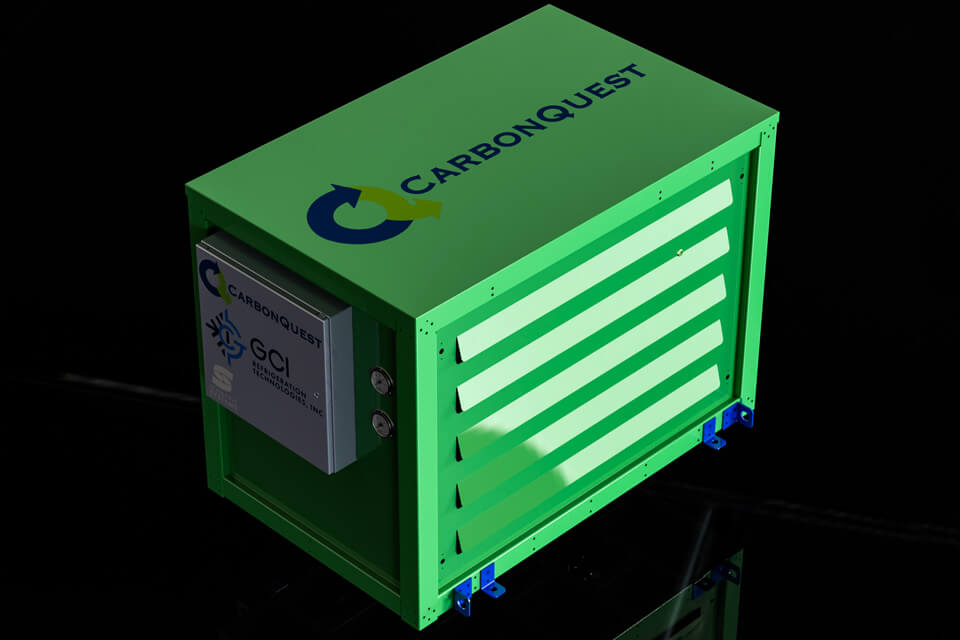

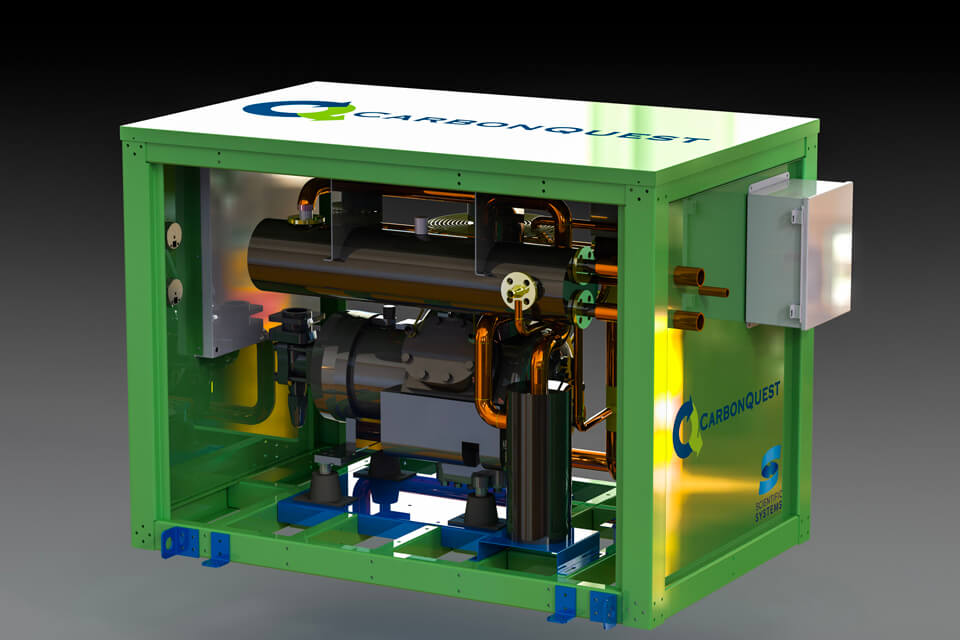

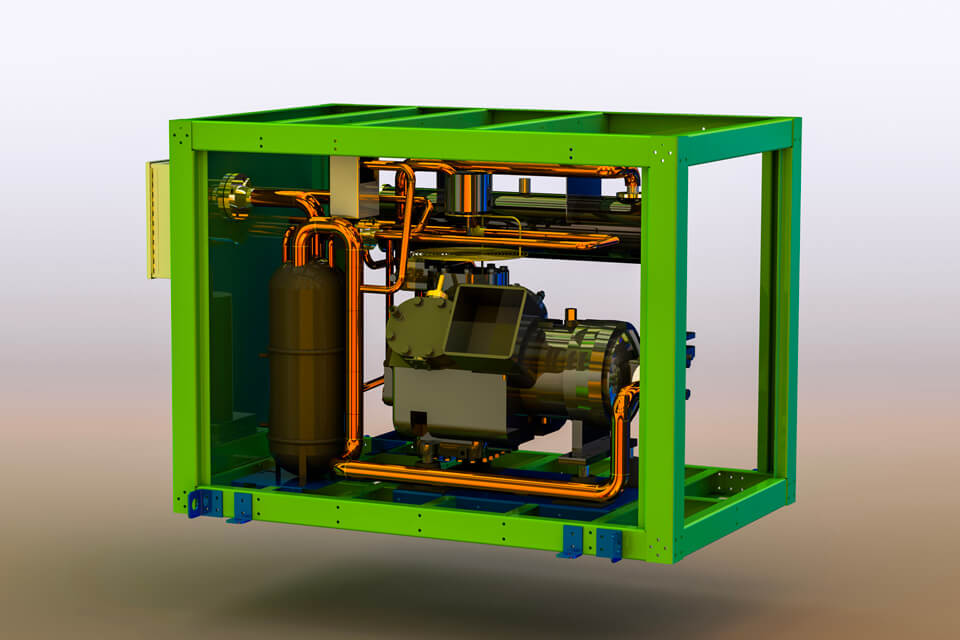

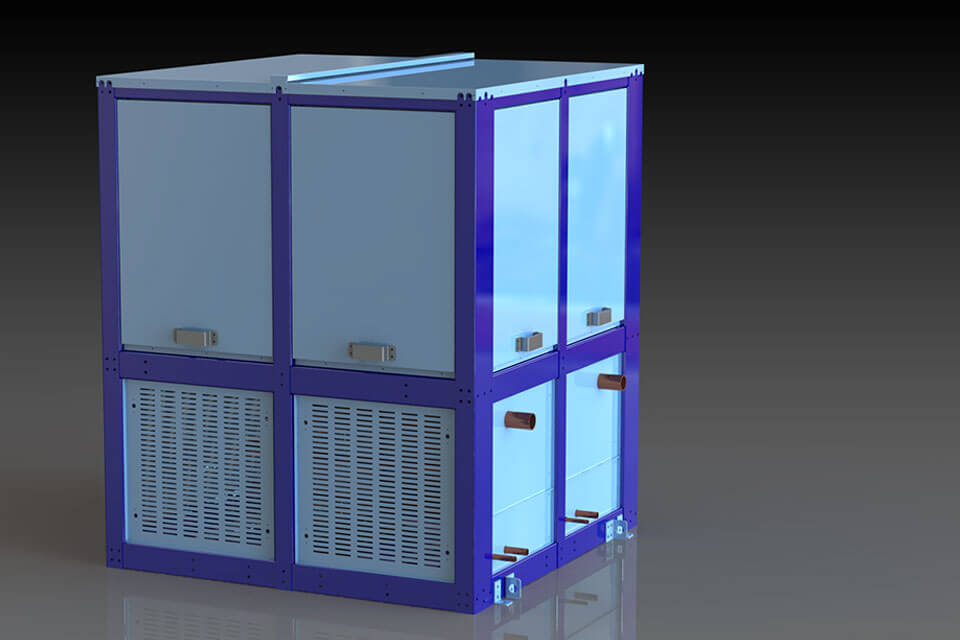

Designed and built by GCI for applications requiring unusually low temperature cooling, the LT and XLT Series Icewagon Chillers perform down to -130°F, well below the operating limits of standard machines. Suitable for soap molding, chemical and polymer processing, printing, ceramic manufacturing, vapor recovery, laboratory apparatus, cryogenics and other specialized applications, these subzero chillers are available in both water and air condensing models in a wide range of capacities.

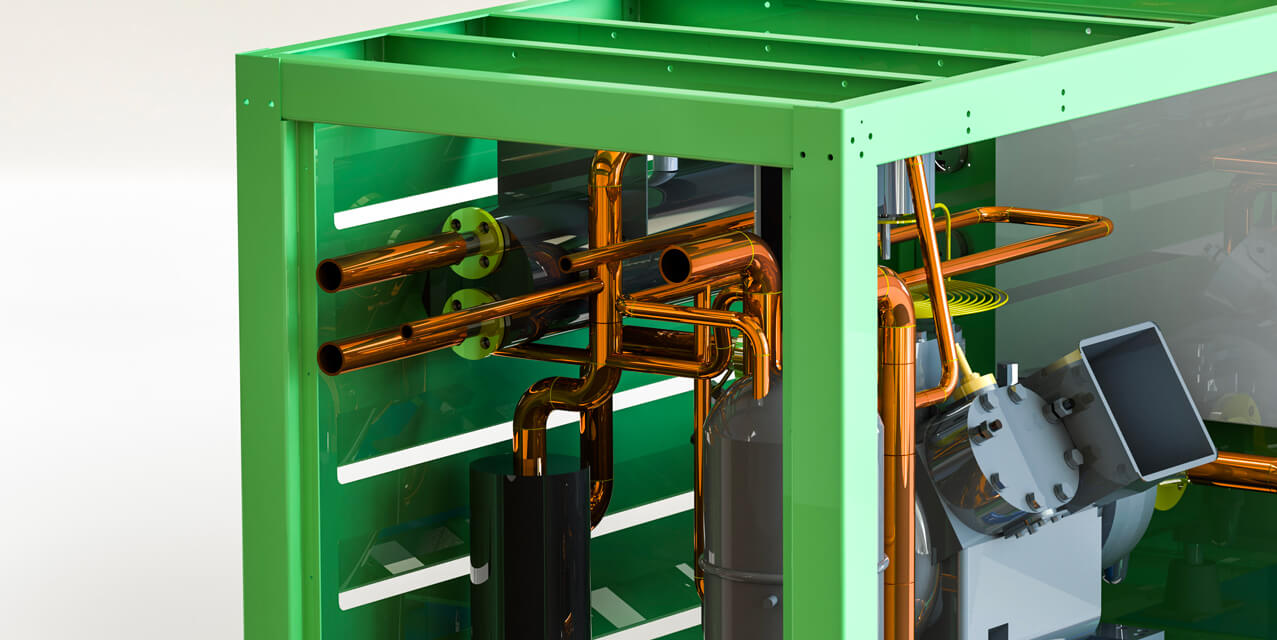

GCI low-temperature process chillers are constructed to be tough, compact in overall size and floor footprint, easy to maintain, and accessible for servicing. The standard LT and XLT models incorporate the same premium features of our heavy-duty portable chillers and have a proven reputation for workhorse performance. Custom low temperature process chillers can be built to customer specification with additional capabilities for specialized low-temperature applications.

GCI is continually upgrading its products. As such, oil specifications are subject to change without notice. Call us at 225-926-6950 for more information on low temperature process chillers and to get help determining your chiller requirements.

How To Order

How to Order Icewagon Chillers

- Determine the preferred medium of cooling, Air or Water.

- Determine required cooling capacity in nominal tons (12,000 BTUH per ton).For computer assisted load calculation contact factory and request Technical Support Bulletin REHV1FRM.

- Determine required voltage configuration. For 50 Hertz models contact factory.

- Determine hazard classification per National Electric Code (NEC). For example Class I, Group D, Division 2.

- Select the model number following the order code.

- Scan the “Options and Accessories” listing below and select the desired items. Order by adding and dash and the Compressor Configuration

- For technical or pricing information contact your representative or Sales Engineering at (225)-926-6950.

Additional Options

Outdoor and split systems. Fully stainless models for food applications. DI water, heaters, special paint, lower temperature models, oversize tanks, special pumps, special currents, special weather proofing

- Copper Fin Coils

- SaveCoil™ Coil Coating

- Type 316 Stainless Steel Housings

- Full Corrosion Protection

- Weatherproof Nema 4

- Explosion Proof Nema 7

- Low Ambient Controls

- 100% Redundant Systems

- Automatic Switch Over

- Epoxy Patin with Urethane Topcoat

- Optional Explosion Proof Disconnect Switch

- Other Options include Defrost Timer, Oil Separator, Solenoid Valves, and Crankcase Pressure Regulator

- Cupro-Nickel Marine Condensers and Low Ambient Controls

| Model Number | Description |

|---|---|

| LAC | Low Ambient Controls, for operating when outdoor ambients are below 55° (13° C) |

| BG | BLYGOLD PoluAL spray-applied coil coating on condenser and evaporator coils, additional |

| ECB | BYLGOLD PoluAL spray-applied coil coating, other metal epoxy primed and coated additional |

| SH | Cover housing, Corrosion Resistant Type 316 stainless steel |

| MBS | Mounting Bracket Set, Type 316 SS, for corrosion-resistant support of SafetyCool Air Conditioners |

| EXP | Export Crate, heavy-duty, for rough handling air or sea shipment specify |

| RC | Remote Controls, thermostat, and selector switch |

| SPS | Spare Parts Kit (thermostat, selector switch, run capacitor) |

| CC | SaveCoil 31 Dip applied and baked coating on condenser and evaporator coils, additional |

| EC | SaveCoil 31 Dip applied and baked coil coating, other metal epoxy primed and coated, additional |

| Model No. | Description |

|---|---|

| OR | Off Road Package – Standard base model. Excludes all features in -HWY package |

| HWY | Highway Ready Package – includes surge brakes, spare tire, light and reflector package, license plate holder, VIN registration and certificate of origin. |

| CD | Condensate Pump – a condensate pump located in the evaporator drain pan allows pumping of condensed moisture to a safe location. |

| EH(*) | Electric Heat – Add electric heat for use in heating and cooling applications. Rugged Finned Tubular heating elements available in 15kW, 40kW, 65 kW, and 90 kW on most models. |

| HP | Heat Pump – Adds reversing cycle for heating for outdoor temperatures above 45°F. |

| CM | Cam Locks – Quick connect Cam Lock electrical plugs replace power line cord. |

| DTI | Digital Temperature Indicators – Two digital displays mounted on the control console display supply and return air temperatures. |

| RT | Remote Thermostat – With 125 ft. cord allows temperature control form within the air-conditioned space. Mount Thermostat inside build for precise control. |

| PLX | Plexiglass Cover – Weather tight door with plexiglass window protects the control panel from the elements while allowing operator to view controls. |

| Model No. | Description |

|---|---|

| / SS | Stainless Steel Housing, 14 ga Type 316 with 16 ga access panels, includes option “/EC” |

| TCXP-C-1101 | Thermostat, “Cool” or “Fan Only,” Class I and II, Groups B, C, and D, Division 1 and 2 |

| TCXP-HC-1101 | Thermostat, “Heat,” “Cool,” or “Fan Only”; Manual Switchover, CI. I and II, Grps. B, C, and D, Div. 1 and 2 |

| / EH(kw) | Auxiliary Electric Heat (*), (specify kw) |

| / SH(MBtuh) | Auxiliary Steam Heater, less trap or control solenoid, (specify MBtuh and supply pressure) |

| / FDI | Disconnect Switch with Circuit Breaker Protection, installed |

| / DSI | Disconnect Switch, non-fused, installed |

| / LAC | Low Ambient Control, for operating at ambient temperatures between 0 and 50°F |

| / HGB | Hot Gas Bypass for capacity control |

| / CC | SaveCoil 101 oven baked coil coating on condenser and evaporator coils |

| / EC | Full Corrosion Protection: Non-stainless metal parts epoxy coated; Coils are SaveCoil 101 protected |

| / SDI | Smoke Detector, installed with system interlock |

| / FAD | Manual Make-Up Air Damper |

| / Cu-Cu | Copper coils and fins in lieu of copper coils w/ aluminum fins. End plates galvanized unless otherwise specified. |

| / MAC | Make-Up Air Inlet Rain Cap |

| / EXP | Export Crate, heavy-duty, for rough handling and marine shipment |

(*) Explosion-proof heaters rated Temp Code T2A unless otherwise specified. Electric heaters for Div. 1 are field installed discharge air duct.

Standard Design And Construction Features for Low Temperature Process Chillers

The following systems, features, and materials of construction are standard in all LT & XLT Series Icewagons:

Optional/Custom Features for Low Temperature Process Chillers

Using the twenty models in the LT & XLT lines as building blocks, we can custom assemble a low temperature process chiller with a combination of features and systems required for almost any low temperature cooling application. Opportunities include the following: