Individually-customized, but built with standard components.

At GCI Refrigeration Technologies, our custom air condensing chillers accommodate a diverse range of industrial applications. Our DH chillers are available in both air-condensing and water-condensing designs.

Air Condensing Chillers

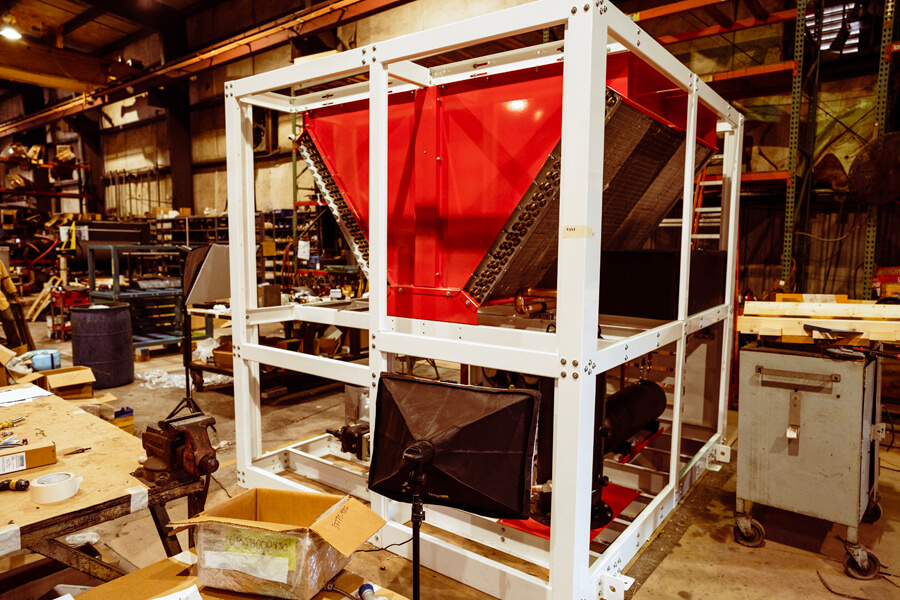

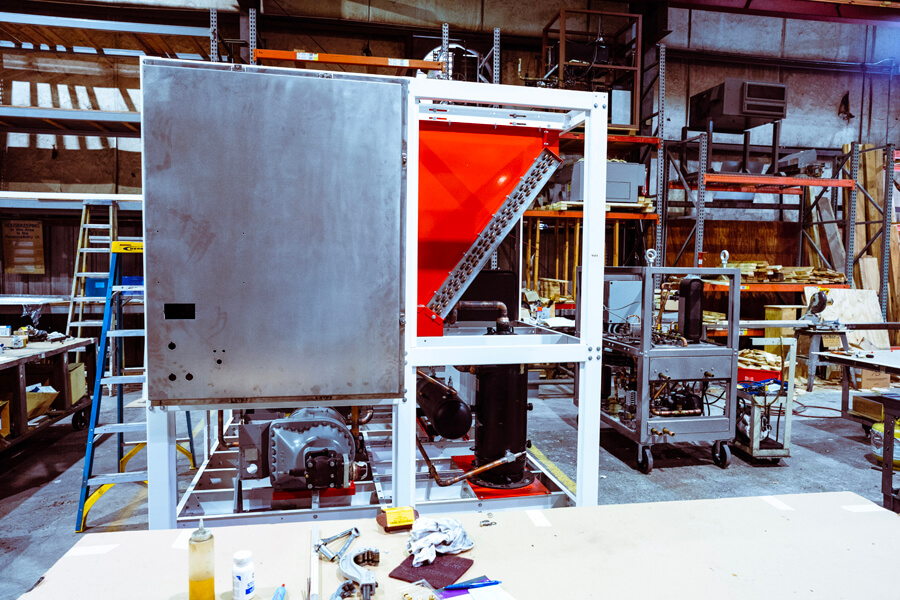

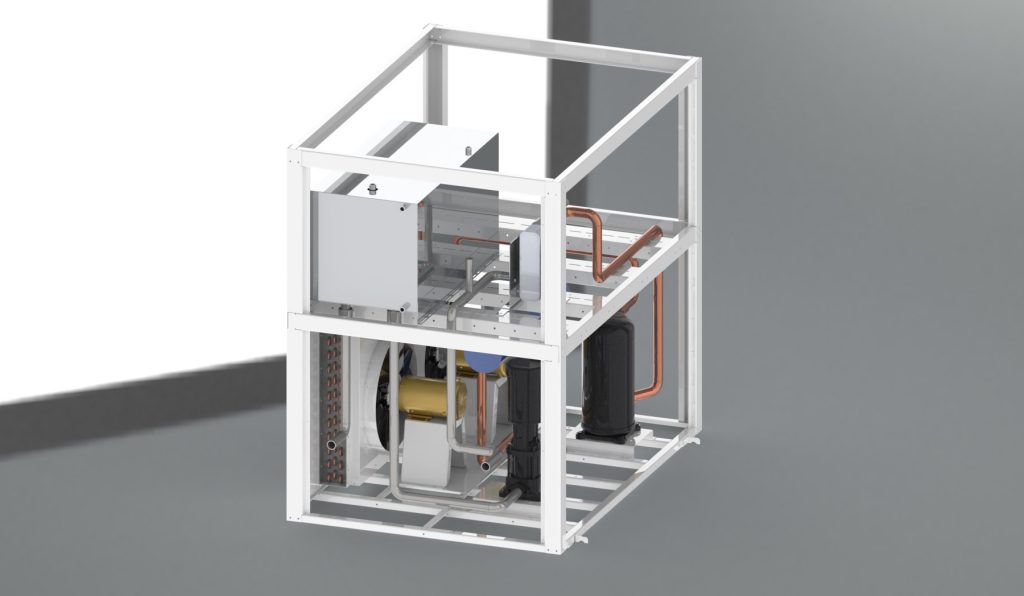

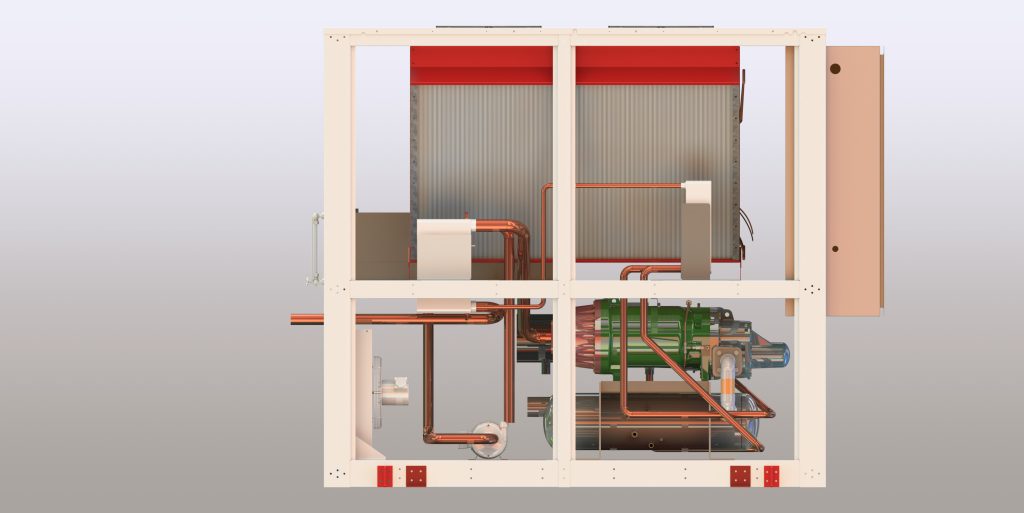

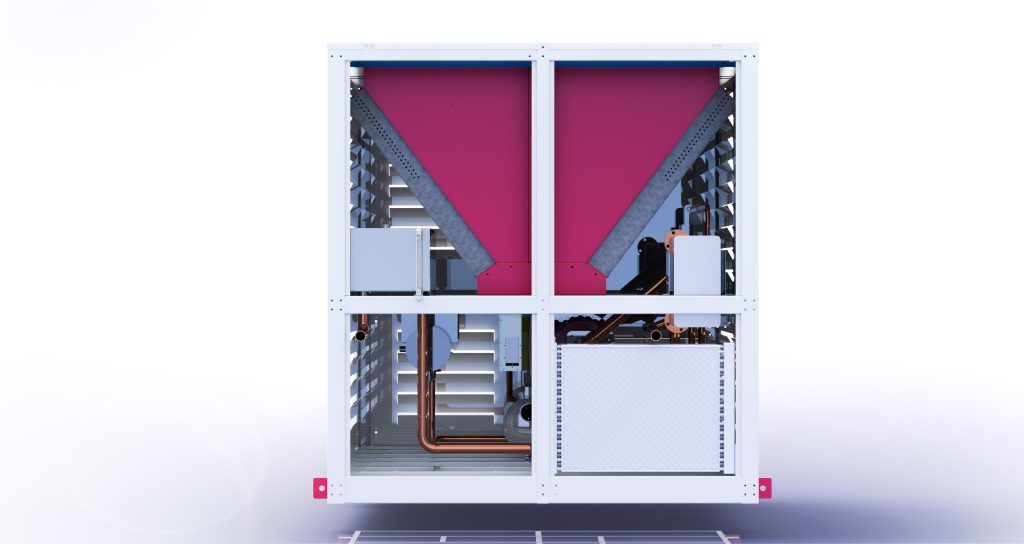

Designed and built by GCI for the most demanding applications, DH Series Icewagon™ chillers are dependable workhorses with a broad range of capacities. Each chiller is built to order with standard components and additional features to ensure reliable operation in critical applications.

Types of Air Condensing Chillers

In addition to our Icewagon™ DH Series air condensing chillers for heavy-duty industrial use, we also manufacture low-temperature air condensing chillers (below -30°F) and extra-low temperature industrial air condensing chillers (below -75°F). Each type of chiller features its own customizable models for specific industrial applications.

As the specifications and dimensions of our products are subject to change, this information is for general purposes only.

Since 1958, our customers have trusted us to provide reliable refrigeration products for their industrial needs. For more information about our DH Series Icewagon™ air condensing chillers, call GCI Refrigeration Technologies at 225-926-6950. If you’re ready to request a free quote, fill out our online form.

FEATURES

- Steel Frame and Covers: A compact, structural steel frame helps protect your air condensing chiller from impact damage, and removable steel panels allow access for routine inspection and maintenance. The frame includes casters or mounting pads.

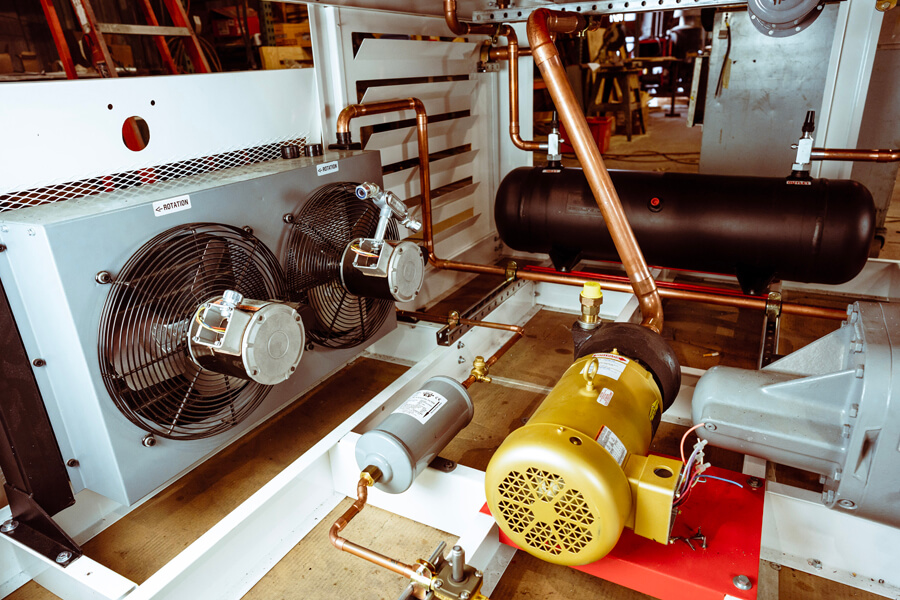

- Dual Compressor Option: DH chillers can be equipped with two compressors—a dual-circuit evaporator and a dual-circuit condenser—and wired for lead-lag performance. This allows one or both systems to operate depending on the seasonal heat load, which provides greater flexibility and can conserve electricity. Using a PLC control, complete dual systems within the same machine can offer total redundancy for critical applications. Three and four compressor models are also available.

- Drop-in Condensers: DH Series chillers feature this unique modular type.

- Hot Gas Bypass: This feature delivers more precise temperature control by eliminating the constant on-off compressor short-cycling that results in excessive component wear and unnecessary power usage.

- Job-specific Evaporators: GCI will fit our own Coilmatic™ high-efficiency evaporator, a special low-flow evaporator, or a space-saving brazed plate evaporator based on your application.

- Secondary Coolant Loops: A frequently selected option for DH Series air condensing chillers is a secondary loop, an additional heat exchanger installed within the chiller between the evaporator and the process. This component may be necessary to reduce the possibility of freezing the evaporator when ethylene glycol or methanol services are the primary coolant and water near 32°F is the secondary coolant. It may also be ideal when the secondary coolant is deionized water, oil, or thermal fluid, or when a large temperature drop is required. Secondary heat exchangers are fully enclosed in the air condensing chiller frame and may be brazed plate, plate and frame, shell and tube, or another design. Secondary pumps and tanks are also common.

- Stainless Steel Pump and Tank: Available for a wide range of coolants, stainless steel offers complete corrosion resistance, and the centrifugal-circulating pump has a high-efficiency impeller, centerline connections, mechanical seal. Vented tanks serve thermal purposes.

- Brazed Copper Piping: Extending throughout GCI air condensing chillers, our brazed copper piping is fully insulated, features bronze valves, and provides longevity, structural integrity, and protection against rust. Piping is optional for deionized water or food applications, stainless steel, or CPVC.

- Microprocessor Control: Controls include an easy-to-use digital thermostat in °F or °C, plus high- and low-pressure refrigerant gauges, pump pressure gauge, tank sight tube, and internal refrigerant sight glass. A remote interface is optional, and extra digital thermometers are available.

- Safety Package: This feature includes a high/low refrigerant pressure safety switch, pressure relief device, motor overload protection, line and control circuit fuses, and pump switch interlock.

- ChillersDirect™: As another benefit to help keep your investment to a minimum, you’ll deal directly with our factory for your air condensing chiller customization. Our experts will help you select the right features so your chiller is just right for your application.

- Ready-to-install: We fully assemble and test all Icewagon™ air condensing chillers to your operating conditions before they leave our plant. Installation is simple, but we encourage you to contact us if you need assistance.

- Extra Options: Outdoor and split systems are available on low and extra-low temperature air-condensing chiller models to -50°F.

How To Order

How to Order Icewagon Chillers

- Determine the preferred medium of cooling, Air or Water.

- Determine required cooling capacity in nominal tons (12,000 BTUH per ton).For computer assisted load calculation contact factory and request Technical Support Bulletin REHV1FRM.

- Determine required voltage configuration. For 50 Hertz models contact factory.

- Determine hazard classification per National Electric Code (NEC). For example Class I, Group D, Division 2.

- Select the model number following the order code.

- Scan the “Options and Accessories” listing below and select the desired items. Order by adding and dash and the Compressor Configuration

- For technical or pricing information contact your representative or Sales Engineering at (225)-926-6950.

Additional Options

Outdoor and split systems. Fully stainless models for food applications. DI water, heaters, special paint, lower temperature models, oversize tanks, special pumps, special currents, special weather proofing

- Copper Fin Coils

- SaveCoil™ Coil Coating

- Type 316 Stainless Steel Housings

- Full Corrosion Protection

- Weatherproof Nema 4

- Explosion Proof Nema 7

- Low Ambient Controls

- 100% Redundant Systems

- Automatic Switch Over

- Epoxy Patin with Urethane Topcoat

- Optional Explosion Proof Disconnect Switch

- Other Options include Defrost Timer, Oil Separator, Solenoid Valves, and Crankcase Pressure Regulator

- Cupro-Nickel Marine Condensers and Low Ambient Controls

| Model Number | Description |

|---|---|

| LAC | Low Ambient Controls, for operating when outdoor ambients are below 55° (13° C) |

| BG | BLYGOLD PoluAL spray-applied coil coating on condenser and evaporator coils, additional |

| ECB | BYLGOLD PoluAL spray-applied coil coating, other metal epoxy primed and coated additional |

| SH | Cover housing, Corrosion Resistant Type 316 stainless steel |

| MBS | Mounting Bracket Set, Type 316 SS, for corrosion-resistant support of SafetyCool Air Conditioners |

| EXP | Export Crate, heavy-duty, for rough handling air or sea shipment specify |

| RC | Remote Controls, thermostat, and selector switch |

| SPS | Spare Parts Kit (thermostat, selector switch, run capacitor) |

| CC | SaveCoil 31 Dip applied and baked coating on condenser and evaporator coils, additional |

| EC | SaveCoil 31 Dip applied and baked coil coating, other metal epoxy primed and coated, additional |

| Model No. | Description |

|---|---|

| OR | Off Road Package – Standard base model. Excludes all features in -HWY package |

| HWY | Highway Ready Package – includes surge brakes, spare tire, light and reflector package, license plate holder, VIN registration and certificate of origin. |

| CD | Condensate Pump – a condensate pump located in the evaporator drain pan allows pumping of condensed moisture to a safe location. |

| EH(*) | Electric Heat – Add electric heat for use in heating and cooling applications. Rugged Finned Tubular heating elements available in 15kW, 40kW, 65 kW, and 90 kW on most models. |

| HP | Heat Pump – Adds reversing cycle for heating for outdoor temperatures above 45°F. |

| CM | Cam Locks – Quick connect Cam Lock electrical plugs replace power line cord. |

| DTI | Digital Temperature Indicators – Two digital displays mounted on the control console display supply and return air temperatures. |

| RT | Remote Thermostat – With 125 ft. cord allows temperature control form within the air-conditioned space. Mount Thermostat inside build for precise control. |

| PLX | Plexiglass Cover – Weather tight door with plexiglass window protects the control panel from the elements while allowing operator to view controls. |

| Model No. | Description |

|---|---|

| / SS | Stainless Steel Housing, 14 ga Type 316 with 16 ga access panels, includes option “/EC” |

| TCXP-C-1101 | Thermostat, “Cool” or “Fan Only,” Class I and II, Groups B, C, and D, Division 1 and 2 |

| TCXP-HC-1101 | Thermostat, “Heat,” “Cool,” or “Fan Only”; Manual Switchover, CI. I and II, Grps. B, C, and D, Div. 1 and 2 |

| / EH(kw) | Auxiliary Electric Heat (*), (specify kw) |

| / SH(MBtuh) | Auxiliary Steam Heater, less trap or control solenoid, (specify MBtuh and supply pressure) |

| / FDI | Disconnect Switch with Circuit Breaker Protection, installed |

| / DSI | Disconnect Switch, non-fused, installed |

| / LAC | Low Ambient Control, for operating at ambient temperatures between 0 and 50°F |

| / HGB | Hot Gas Bypass for capacity control |

| / CC | SaveCoil 101 oven baked coil coating on condenser and evaporator coils |

| / EC | Full Corrosion Protection: Non-stainless metal parts epoxy coated; Coils are SaveCoil 101 protected |

| / SDI | Smoke Detector, installed with system interlock |

| / FAD | Manual Make-Up Air Damper |

| / Cu-Cu | Copper coils and fins in lieu of copper coils w/ aluminum fins. End plates galvanized unless otherwise specified. |

| / MAC | Make-Up Air Inlet Rain Cap |

| / EXP | Export Crate, heavy-duty, for rough handling and marine shipment |

(*) Explosion-proof heaters rated Temp Code T2A unless otherwise specified. Electric heaters for Div. 1 are field installed discharge air duct.

APPLICATIONS

- Customized air condensing chillers from GCI Refrigeration Technologies are built for rigorous industrial applications, including:

- Food

- Pharmaceuticals

- Biotechnology

- Plastics and rubber

- Chemicals

- Metalworking

- Nuclear Science

Confidentiality Notice

This drawing and information contained herein are the exclusive property of Scientific System LLC and shall be returned upon demand and shall not be reproduced in whole or in part, disclosed to anyone else or used, without written consent of Scientific Systems LLC.