High-Quality Process Chillers

Customized Chillers for Industrial Applications

Industrial process chillers are used in a wide variety of applications that require chilled water, oil, and gas cooling process loop. These applications relate to many industries like the ones we have listed below and many more.

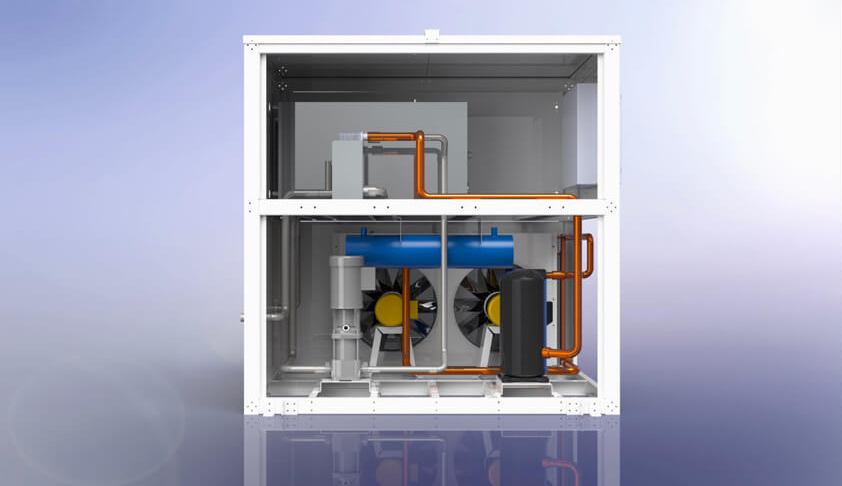

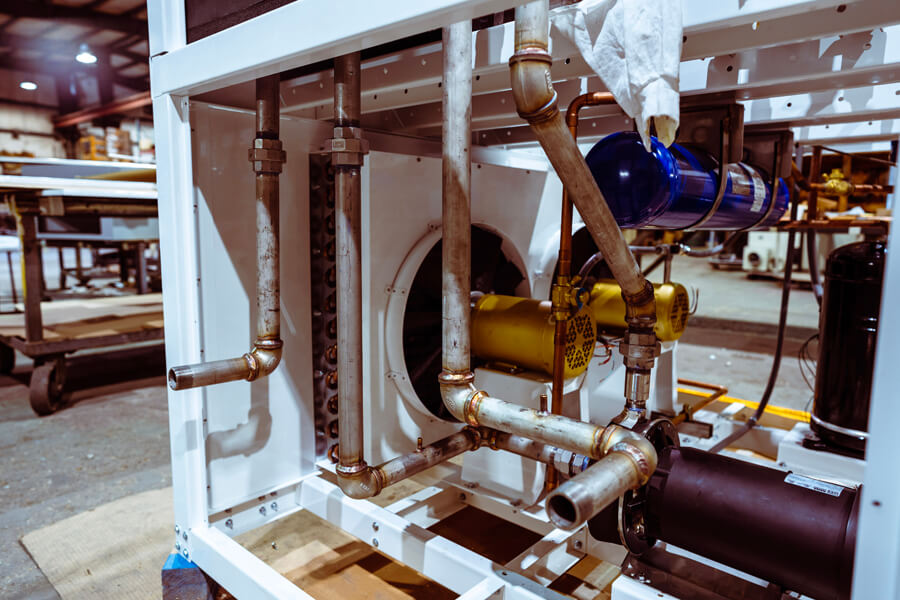

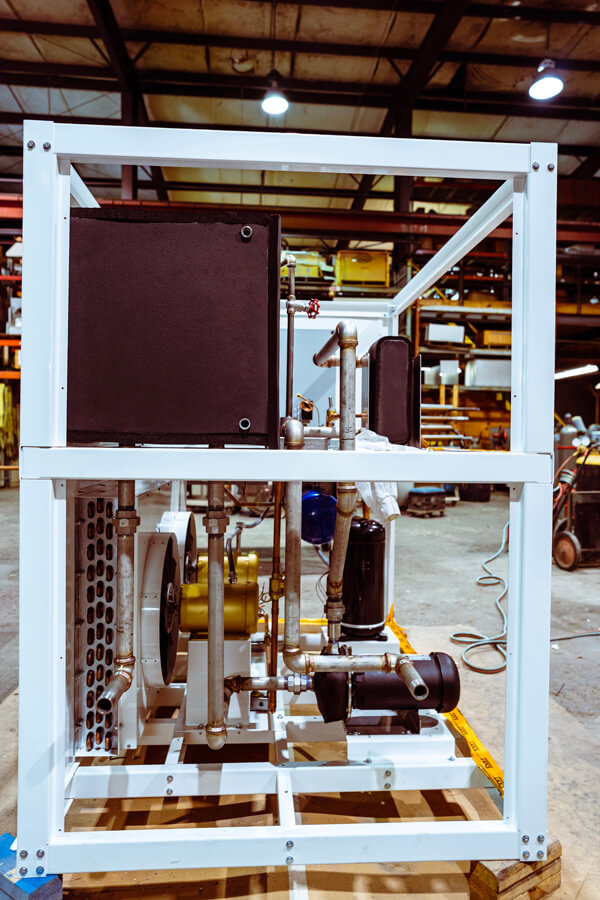

The function of a process chiller is to remove heat from one location, which usually is the process equipment or the actual medium of product, to another location. This location is usually outside the facility and away from all processes to maintain efficiency and cost-effectiveness. Our process chillers most commonly use a water/glycol solution to remove heat, transfer the fluid through the industrial process, and recirculate to form a cooling loop designed specifically for the industrial process it was manufactured for. This allows us to utilize a reservoir and pump system all built into one turnkey solution.

Why Do You Need an Industrial Process Chiller?

In the realm of real-world physics that we are bound by, there is nothing that is 100% efficient. No motor, machine, or process can avoid the energy lost to heat or work. If this heat is not removed from the system, the process becomes slow, inefficient, and cost heavy over time. Nobody wants to shut down their plant for maintenance or, even worse, equipment failure. Without process cooling from process chillers, the industry would be plagued with these issues.

Using our ICEWAGON Chillers will provide constant temperature and pressure control over your industrial process. With our process chiller handling this process, you can rest easy knowing that our ICEWAGON is keeping your industry safe and efficient.

How To Order

How to Order Icewagon Chillers

- Determine the preferred medium of cooling, Air or Water.

- Determine required cooling capacity in nominal tons (12,000 BTUH per ton).For computer assisted load calculation contact factory and request Technical Support Bulletin REHV1FRM.

- Determine required voltage configuration. For 50 Hertz models contact factory.

- Determine hazard classification per National Electric Code (NEC). For example Class I, Group D, Division 2.

- Select the model number following the order code.

- Scan the “Options and Accessories” listing below and select the desired items. Order by adding and dash and the Compressor Configuration

- For technical or pricing information contact your representative or Sales Engineering at (225)-926-6950.

Additional Options

Outdoor and split systems. Fully stainless models for food applications. DI water, heaters, special paint, lower temperature models, oversize tanks, special pumps, special currents, special weather proofing

- Copper Fin Coils

- SaveCoil™ Coil Coating

- Type 316 Stainless Steel Housings

- Full Corrosion Protection

- Weatherproof Nema 4

- Explosion Proof Nema 7

- Low Ambient Controls

- 100% Redundant Systems

- Automatic Switch Over

- Epoxy Patin with Urethane Topcoat

- Optional Explosion Proof Disconnect Switch

- Other Options include Defrost Timer, Oil Separator, Solenoid Valves, and Crankcase Pressure Regulator

- Cupro-Nickel Marine Condensers and Low Ambient Controls

| Model Number | Description |

|---|---|

| LAC | Low Ambient Controls, for operating when outdoor ambients are below 55° (13° C) |

| BG | BLYGOLD PoluAL spray-applied coil coating on condenser and evaporator coils, additional |

| ECB | BYLGOLD PoluAL spray-applied coil coating, other metal epoxy primed and coated additional |

| SH | Cover housing, Corrosion Resistant Type 316 stainless steel |

| MBS | Mounting Bracket Set, Type 316 SS, for corrosion-resistant support of SafetyCool Air Conditioners |

| EXP | Export Crate, heavy-duty, for rough handling air or sea shipment specify |

| RC | Remote Controls, thermostat, and selector switch |

| SPS | Spare Parts Kit (thermostat, selector switch, run capacitor) |

| CC | SaveCoil 31 Dip applied and baked coating on condenser and evaporator coils, additional |

| EC | SaveCoil 31 Dip applied and baked coil coating, other metal epoxy primed and coated, additional |

| Model No. | Description |

|---|---|

| OR | Off Road Package – Standard base model. Excludes all features in -HWY package |

| HWY | Highway Ready Package – includes surge brakes, spare tire, light and reflector package, license plate holder, VIN registration and certificate of origin. |

| CD | Condensate Pump – a condensate pump located in the evaporator drain pan allows pumping of condensed moisture to a safe location. |

| EH(*) | Electric Heat – Add electric heat for use in heating and cooling applications. Rugged Finned Tubular heating elements available in 15kW, 40kW, 65 kW, and 90 kW on most models. |

| HP | Heat Pump – Adds reversing cycle for heating for outdoor temperatures above 45°F. |

| CM | Cam Locks – Quick connect Cam Lock electrical plugs replace power line cord. |

| DTI | Digital Temperature Indicators – Two digital displays mounted on the control console display supply and return air temperatures. |

| RT | Remote Thermostat – With 125 ft. cord allows temperature control form within the air-conditioned space. Mount Thermostat inside build for precise control. |

| PLX | Plexiglass Cover – Weather tight door with plexiglass window protects the control panel from the elements while allowing operator to view controls. |

| Model No. | Description |

|---|---|

| / SS | Stainless Steel Housing, 14 ga Type 316 with 16 ga access panels, includes option “/EC” |

| TCXP-C-1101 | Thermostat, “Cool” or “Fan Only,” Class I and II, Groups B, C, and D, Division 1 and 2 |

| TCXP-HC-1101 | Thermostat, “Heat,” “Cool,” or “Fan Only”; Manual Switchover, CI. I and II, Grps. B, C, and D, Div. 1 and 2 |

| / EH(kw) | Auxiliary Electric Heat (*), (specify kw) |

| / SH(MBtuh) | Auxiliary Steam Heater, less trap or control solenoid, (specify MBtuh and supply pressure) |

| / FDI | Disconnect Switch with Circuit Breaker Protection, installed |

| / DSI | Disconnect Switch, non-fused, installed |

| / LAC | Low Ambient Control, for operating at ambient temperatures between 0 and 50°F |

| / HGB | Hot Gas Bypass for capacity control |

| / CC | SaveCoil 101 oven baked coil coating on condenser and evaporator coils |

| / EC | Full Corrosion Protection: Non-stainless metal parts epoxy coated; Coils are SaveCoil 101 protected |

| / SDI | Smoke Detector, installed with system interlock |

| / FAD | Manual Make-Up Air Damper |

| / Cu-Cu | Copper coils and fins in lieu of copper coils w/ aluminum fins. End plates galvanized unless otherwise specified. |

| / MAC | Make-Up Air Inlet Rain Cap |

| / EXP | Export Crate, heavy-duty, for rough handling and marine shipment |

(*) Explosion-proof heaters rated Temp Code T2A unless otherwise specified. Electric heaters for Div. 1 are field installed discharge air duct.

How Does an Industrial Process Chiller Work?

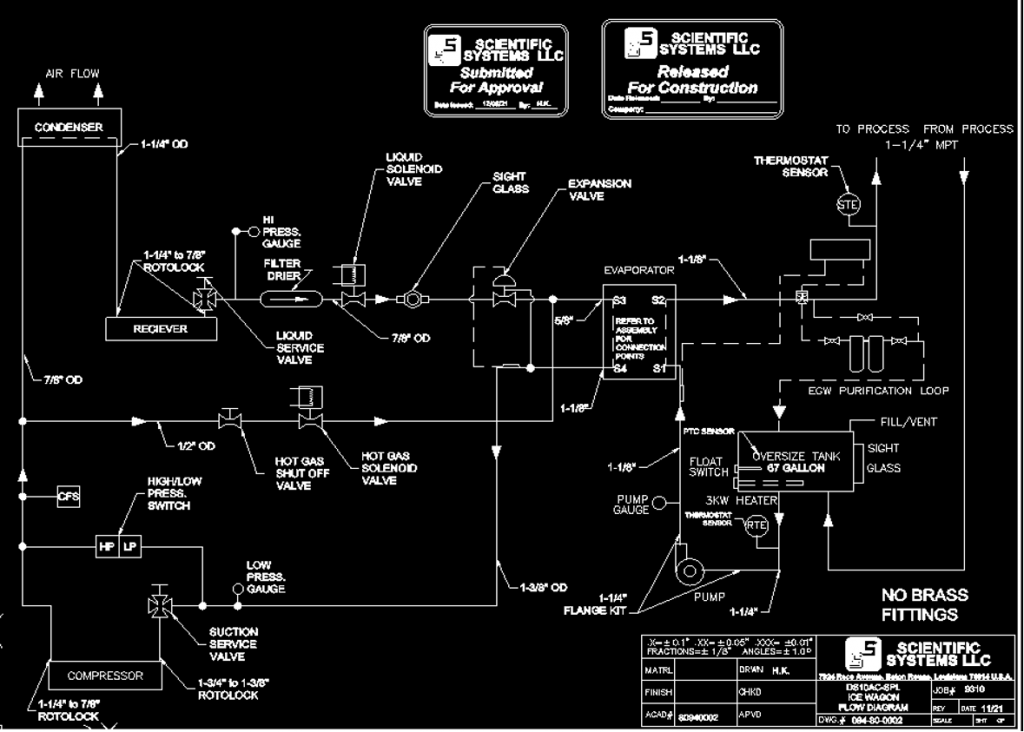

Now that we have established what a process chiller does and why you might need one, you might wonder how it works. In most cases, a pumping system circulates a cold water or glycol-water solution out of the process chiller into the industrial process. The cooling medium from the process chiller then removes heat from the process, and the medium, now heated, returns to the process chiller to reenter the loop of cooling and back to the industrial process. This cooling is achieved with a chemical compound of HFC (hydrofluorocarbons) refrigerants.

There are a multitude of different refrigerants which all serve a purpose towards unique application-based or temperature-based processes. They all boil down to the same principle of compression and phase change of the refrigerant from liquid to gas and gas to liquid. This cycle of heating and cooling is the crux of the refrigeration cycle.

This cycle, as seen below in our refrigeration diagram, begins with a low-pressure liquid/gas mixture entering the evaporator. In the evaporator, heat from the process solution boils the refrigerant, which changes it from a low-pressure liquid to a low-pressure gas which then enters the compressor to become a high temperature – high-pressure gas. This then enters the condenser where the ambient air or, if this is a water chiller, the condenser water removes the heat to cool it to a high-pressure liquid which then travels to the expansion valve, which regulates the amount of liquid refrigerant enters the evaporator. This cycle loops over and over to provide a consistent temperature and pressure required for the industrial processes these are designed for.

Industrial Process Chillers We Offer

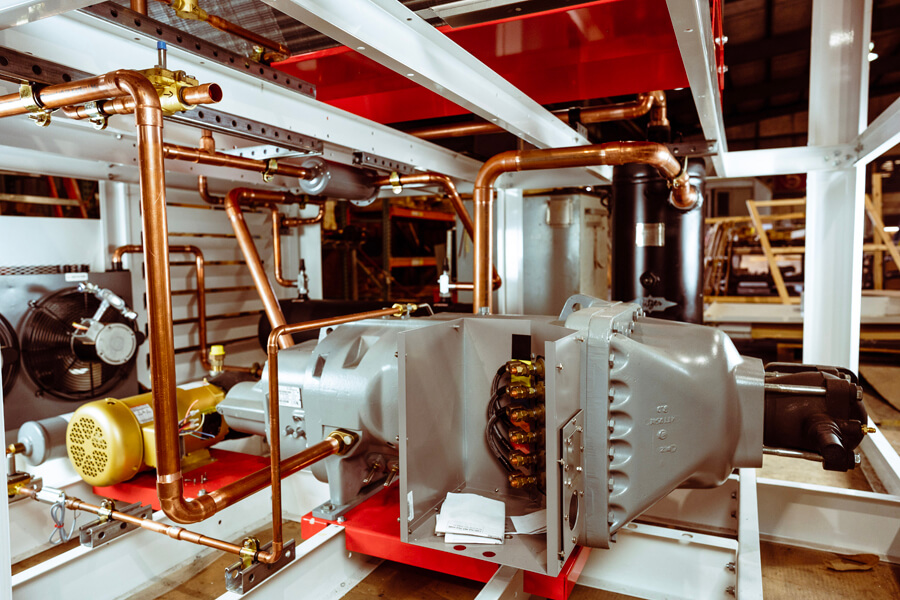

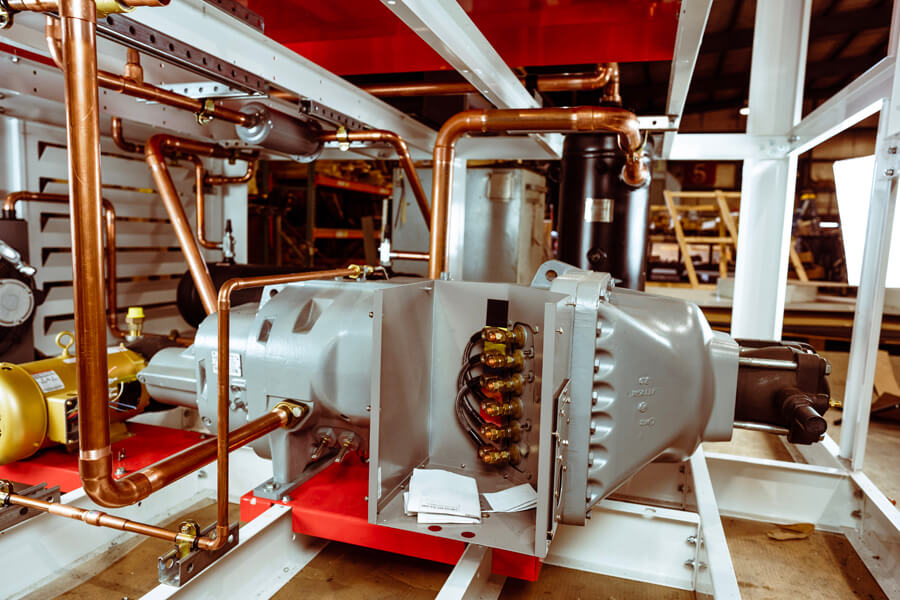

Custom Industrial Chillers

When a standard machine does not meet your standards, you need a custom solution that works for you. Whether your custom industrial process chiller needs corrosion resistance, special controls, or unique safety features, we work closely with you to design and build a machine that fits your needs.

Explosion Proof Chillers

We provide process chillers that have special protection and safety features to prevent damage in harsh or hazardous environments.

Water Cooled Chillers

Designed and built for the most demanding applications in food, pharmaceuticals, biotechnology, plastics and rubber, metalworking, and more. Discover how our water-cooled chillers can guarantee consumer health and safety as well as product quality.

Oil/Fluid Chillers

Our oil and fluid process chillers are designed to handle the transfer of specialized heat fluids used in the operation of manufacturing and process equipment.